Technological advancements are critical to the expansion of the global economy. Developments that improve the efficiency and long-term viability of the entire manufacturing process are among the latest manufacturing trends.

The manufacturing industry saw substantial change in 2021 due to things like industrial revolution 4.0 and the COVID-19 pandemic. These adjustments are also expected to continue in the coming years.

This article will highlight eight major industrial shifts of 2022.

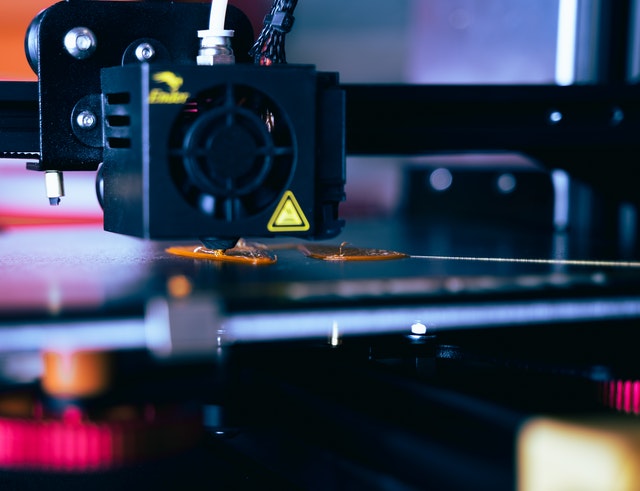

3D Printing

3D printing is an excellent example of the current technology that has had and will continue to have a significant impact on the industry in the coming year. 3D printing allows for the manufacturing of more dependable and efficient components in a faster and more resource-efficient manner.

Overall production efficiency improves because of this. Many things can now be manufactured using 3D printing. They include things like engine components, electronics and some food products. Generally, 3D printing has had a significant impact on business product manufacturing.

Industrial Automation

All process and equipment innovations have aimed to deploy and improve production with automation since the dawn of the industrial revolution. The decrease of human involvement in tedious and potentially hazardous operations makes the production processes safer and saves businesses money. However, as factory automation rises, the cost and complexity of such automated machinery rise exponentially.

Recent advancements in systems and robotics, on the other hand, make installation simple and cost-effective. As a result, robotic automation is the most essential of all the production trends. A good example of this is the flat bed die cutting and its ability to produce hundreds of the same product in seconds.

Industrial automation has simplified material management, assembly, paintwork, and many other manufacturing and finishing processes.

Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, is a concept coined to characterize contemporary manufacturing trends toward “smart factories.” Many of the trends on this list help bring Industry 4.0 to life.

The latest industrial technologies, such as IoT, cloud computing, sophisticated computing, robotics, and human labor, are widely acknowledged and understood to help Industry 4.0 succeed. Companies that wish to stay relevant, competitive, and successful in the marketplace must need to take advantage of this technological advancement.

Internet of Things

Manufacturers can use the Internet of Things (IoT) to link and monitor many aspects of their organization to acquire unique insights. This link provides producers with useful information that can be used to adjust, optimize, and improve every component of the production process.

The Internet of Things (IoT) is pushing industry advancement with sensor devices and internet-enabled cloud connectivity. Companies use IoT capabilities to improve security, cut costs, streamline manufacturing, and develop new products.

Universal Connectability

Traditionally, industrial technologies and advances were marketed as a one-size-fits-all answer. Manufacturers’ options were limited, and certain capabilities were unattainable since operations had to match the pattern of the technology. That balance is evolving as a result of new production practices.

The concept of universal Connectability, as it is coined, means that systems are now being designed to work with any device on a network. In other words, technology and manufacturing breakthroughs can now be tailored to your specific operations without the high cost of a fully customized solution.

Enterprise Planning

ERP (Enterprise Resource Planning) technology has long been utilized in the manufacturing industry. Still, cloud-based SaaS choices that are faster to adopt and cheaper for small enterprises make it even more popular.

ERP solutions enable manufacturers to automate several operating areas through a single system. Manufacturers can use this global touchpoint to evaluate the industrial manufacturing process to make changes and modifications as needed.

The Cloud

The data collected by IoT devices on production lines has the potential to completely revolutionize manufacturing operations. All statistical and analytical activities in traditional systems are carried out on internal hardware and processors.

This raises the costs of building up and supporting sophisticated IT infrastructure and restricts distant employees’ access to data. Cloud-based technologies minimize the need for costly computer equipment and servers while allowing data to be shared across multiple platforms.

Cloud computing is a well-established industrial trend that allows on-premise and remote users to cooperate in real-time. This manufacturing strategy enhances the manageability and lowers network maintenance costs.

Artificial Intelligence

Now that companies have access to more data than ever before, they can use tools such as artificial intelligence(AI) and machine learning to get the most out of that data, which in turn has a huge impact on the manufacturing industry.

AI does not imply a walking or speaking robot but rather a computer system function that recognizes patterns and draws appropriate conclusions to help manufacturers make data-based decisions.

These and many more trends will continue to influence change in business product manufacturing trends in 2022 and well into the future.

Apart from this if you are interested to know more about Light Manufacturing: You Need To Know About Light Manufacturing then visit our Small Businesses category.